| Converter Dia. | Bolt Circle | Thread Size |

|---|---|---|

| 8" steel | 3 on 10.750" bc | 7/16-20 |

| 8" alum | 3 on 10.750" bc | 7/16-20 |

| 8" alum | 6 on 10.750" bc | 7/16-20 |

| 9" steel | 3 on 10.750" bc | 7/16-20 |

| 9" alum | 6 on 10.750" bc | 7/16-20 |

| Converter Dia. | Bolt Circle | Thread Size |

|---|---|---|

| 10" steel | 3 on 10.750" bc | 7/16-20 |

| 10" steel | 6 on 10.750" bc | 7/16-20 |

| 10" alum | 6 on 10.750" bc | 7/16-20 |

| 10" Big Option | 6 on 11.500" bc | 7/16-20 |

| 10" Multi Option | 3 on 10.750" 3 on 11.500" bc | 7/16-20 |

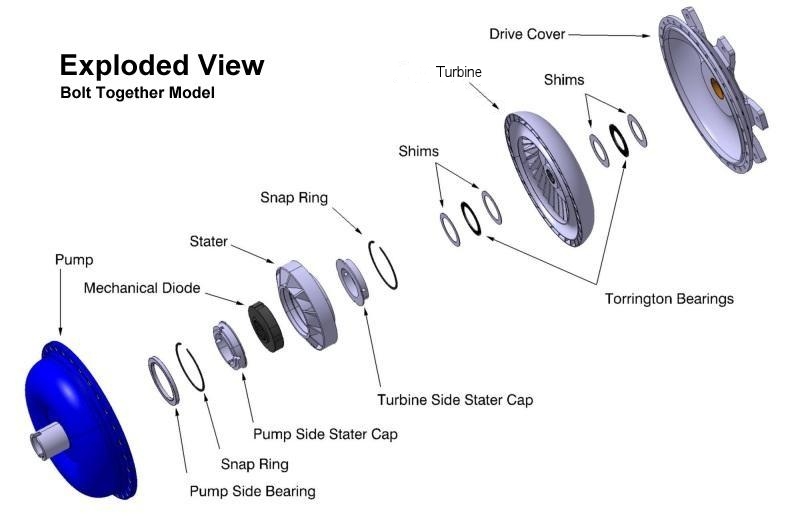

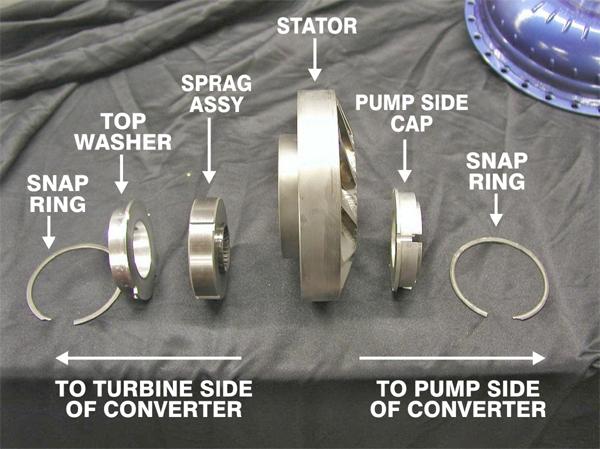

When discussing your torque converter with NCRC, or with other racers, it is helpful to have a clear understanding of what the different component parts are called.

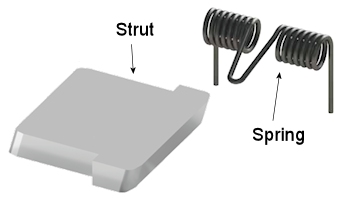

Neal Chance uses the following style Mechanical Diodes in converter assemblies. The NCRC Regular Diode has 5 Stuts, our Monster Diodes are the ones with 10 Struts. Here is a list of the relevant NCRC Freshen Kit Part Numbers for reference:

| PN# GM-MD | Chevy Style 5 Strut Diode Kit |

| PN# GM-MD12 | Chevy Style 10 Strut Diode Kit |

| PN# FD-MD | Ford Style 5 Strut Diode Kit |

| PN# FD-MD12 | Ford Style 10 Strut Diode Kit |

| PN# FMX-MD12 | 10 Strut for 1 3/16" Input Shaft Transmissions |

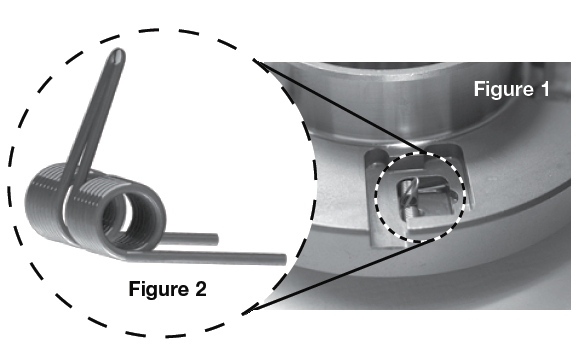

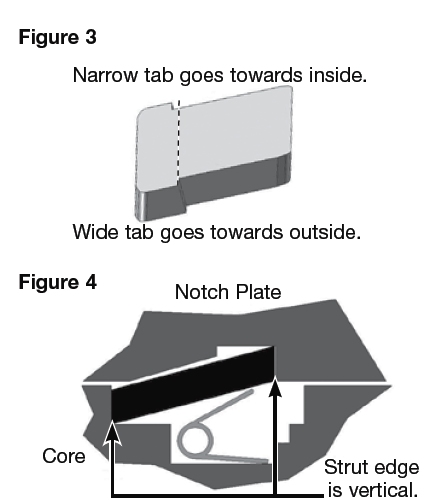

Assembly of Mechanical Diode

Orient the spring as shown in Figure 2. When installed correctly, the spring will look like the one shown in Figure 1.

Orient the spring as shown in Figure 2. When installed correctly, the spring will look like the one shown in Figure 1.

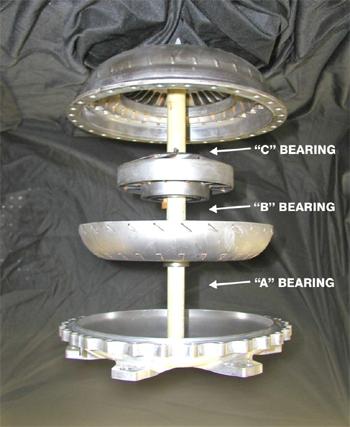

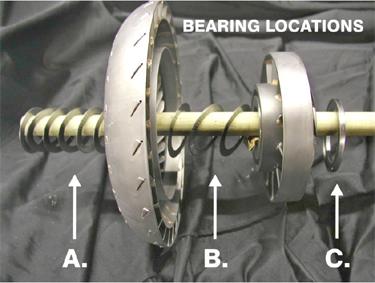

In the converter there are a total of 3 bearings. They include 1 self enclosed bearing on the pump side of the stator (C) and 2 ea. Torrington style bearings, 1 ea. between the stator and the turbine, and 1 ea. between the turbine and drive cover.

NOTE: that on the Torrington style bearing a race is mandatory on both sides of the bearing and any extra races are used as shims.

IMPORTANT: An "O" ring is required to seal the pump and drive cover. NEVER reuse an "O" ring or substitute another product in its place. Failure to do so may result in damage to the product with serious results.

Torque specs on the bolts around the converter are 17-20 ft. lbs. Do Not Over Torque!! Make sure and use a star pattern for the first 8 bolts tightened.

To shim the converter to "full loose" move the extra shims (3 maximum) to the area between the turbine and stator.

NOTE: that the shims must remain the same size and you may have to order shims to complete this operation. If your converter has different size races then keep in mind you must remove from one side and then add to the other keeping the same number of shims as you started with.

To shim the converter "full tight" move all extra shims to the area between the turbine and drive cover. NOTE that the shims must remain the same size and you may have to order shims to complete this operation. If your converter has different size races then keep in mind you must remove from one side and then add to the other keeping the same number of shims as you started with.